Hydrogen: Fichtner H₂-Optimizer

From the Idea to a Functioning Tool for Optimizing, Evaluating and Dimensioning Hydrogen Systems

Be it for investors, project developers or future operators – I have dealt with similar questions from our clients time and again: “How should an electrolyzer be designed and operated? What is the optimum H2 storage capacity? How high are the hydrogen production costs? Is it all worth it economically?“ About a year ago, I finally came to a decision to develop a modeling tool capable of answering such questions at a high level and, at the same time, efficiently, without having to build a separate optimization model from scratch for each individual hydrogen project. And so the basic idea for the Fichtner H2-Optimizer was born.

Theory and practice

My aim was to create a universally valid modeling tool for hydrogen systems. The basic configuration was to include as many different components of typical hydrogen systems as possible, e.g. electrolyzer, compressor, ancillary systems, battery and storage facilities, as well as power supply from renewable energy plants or from the power grid. Different hydrogen markets would, of course, also have to be included, such as reconverting H2 to electricity, feeding it into the natural gas grid, using it as a raw material in industry or in mobility applications, or processing it into “green chemicals”. Based on this objective, I pursued my vision and incorporated a great many systems and options from the hydrogen economy into a universal model enabling systems, procurement options and markets to be added or removed to suit the client’s specific needs. For the key components, I also wanted to implement optional, automated dimensioning which takes CAPEX into account. That was the theory…

This clearly defined objective proved to be considerably more work than expected when it came to developing the tool. Even though I have been using the BoFiT optimization software very intensively for nearly four years now, the goals I set myself stretched me to the limit and ended up requiring the occasional night shift. But all good things come to those who wait!

The H2-Optimizer has become a success. It meets our clients’ requirements and has helped us to win many new orders. We take great pride in the fact that the tried-and-tested H2-Optimizer exceeds our expectations and comprehensively addresses the questions listed above in the introduction.

What is this powerful optimization tool capable of?

The H2-Optimizer provides a complete overview of a hydrogen project. It not only enables the calculation of key figures such as hydrogen production costs, but also the technical dimensioning of individual complex components (e.g. electrolyzer, storage and power generation capacities). On top of this, we enable various sales markets to be depicted. The tool does so by accessing demand, power generation and price profiles and calculating the best possible combination of technologies for the hydrogen project based on models of a wide variety of technical options. All this is done taking into account the applicable conditions and constraints of the hydrogen system in question as well as the underlying value chain. The project-specific models are also continually supervised by Fichtner’s hydrogen experts.

In use worldwide

I am very happy that the H2-Optimizer is being used worldwide for hydrogen projects. The following two projects in particular have stuck in my mind, and I would like to provide a closer look at them in order to illustrate the wide range of tasks performed by our H2-Optimizer:

Innovative sector coupling project with H2

In this project, Fichtner has been contracted as owner’s engineer by the client ‘TIWAG’ to design and engineer an innovative power-to-X plant in Kufstein, Austria which will produce both hydrogen and heat. This will be achieved with the help of power drawn from TIWAG’s own ‘Langkampfen’ run-of-river hydropower plant, from its own solar plant and from the grid. In addition to the waste heat from electrolysis in the power-to-gas plant, the extra heat from the power-to-heat plant is to be fed into the city of Kufstein’s district heating grid. The hydrogen produced will be delivered to end customers at the associated hydrogen filling station or to large customers via trailer or direct pipeline. There are a great many variables to consider in this project as well – both on the power generation and heat offtake side as well as on the projected hydrogen sales side.

Using the H2-Optimizer, our hydrogen team managed to model and optimize the plant concept for TIWAG in the design phase.

Feasibility analysis on producing green hydrogen in India and processing it into green methanol and ammonia

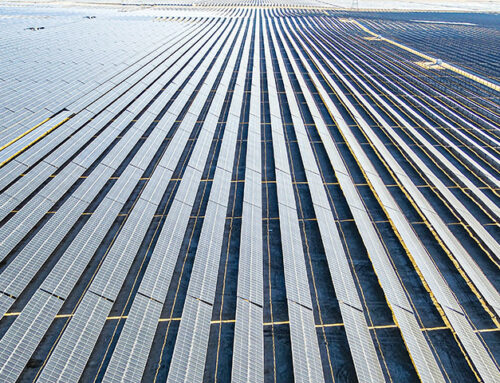

Due to the increasing share of renewable energy sources and international efforts to achieve decarbonization, producing green chemicals such as methanol and ammonia is becoming ever more important also in India. A feasibility report in collaboration with Fichtner India for a large Indian energy provider and an international technology supplier therefore served to illustrate how green hydrogen could be produced from power fed in from a floating solar PV plant belonging to the local energy provider in Ramagundam. The H2-Optimizer provided effective support for this project. Many options for power procurement were assessed, and the optimum plant layout was selected based on the results. Ultimately, the hydrogen produced can be used for ammonia and methanol production.

I look forward to seeing what future projects will be supported by the H2-Optimizer to further the decarbonization of our economy. If you would like to know more about the H2-Optimizer, please take a look at the H2-Optimizer Flyer. You could also visit our new Fichtner Hydrogen Microsite. And, of course, you can always contact me and our hydrogen team. We always look forward to supporting our clients individually and effectively in their projects.

April 2021

Dr. Florian Klumpp

Hydrogen Expert and Managing Director

of Fichtner Australia Pty Ltd